Ju Teng International insists

on providing its clients with the most advanced

production processes, innovation and technical

breakthroughs. In addition to massive investments

in research and development (R& D) each year,

Ju Teng International also forms alliances with

international companies in order to exchange

experiences, so as to offer a variety of the

latest production processes to its clients.

Ju Teng International believes

that only through various verifications can each

production process be performed with perfection

and that a production process is successful only

when it is developed from the perspective of mass

production, completed with a market survey,

evaluated in terms of feasibility and reliability

evaluation, and combined with current trends of

style.

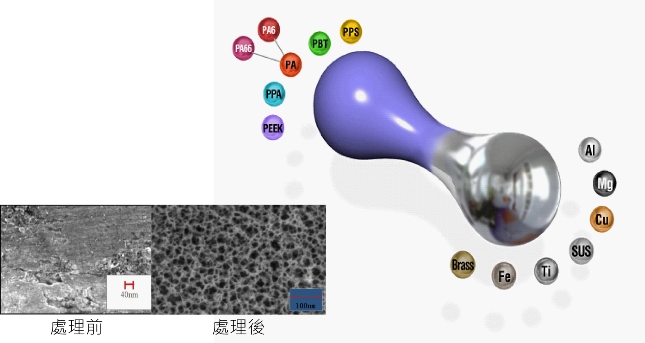

Nano Molding Technology(NMT)

| |

NMT is the technology used as combining plastic and metal. After nanosizing the metal surface,

rigid plastic will be injected on the metal surface directly which makes metal and plastic can be integrally formed.

This technology aims to enhance quality of appearance and simplify design of product structure which makes product to be more lightly and slightly.

Anodizing(NMT)

Anodizing is a type of passivation used to increase thickness of oxide coating on metal surface.

Normally Aluminum alloy is easy to oxidize. Even though oxide coating has the feature of passivation, after exposing for long term,

coatings would drop and have been lacked of protection. Therefore, due to oxidability of materials,

anodizing is utilized to control generating of oxide coating, prevent from additional oxiding of Alumni and enhance mechanical feature on surface.

Moreover, anodizing can produce different colors through formation to improve appearance on surface.

Thermoset /Thermoplastic Composite material application

JuTeng provides thermoset and thermoplastic composite material application. With rigid and high strength of composite materials,

JuTeng combines materials to compressing and insert-molding technology to provide extra choices for Ultrabook to approach to be slightly.

According to specified requirement from customers, JuTeng provides variable laminated methods, resin system, and fabrics for application.

• For types of fabrics, JuTeng has acquired experience on producing carbon fibers, glass fibers, Kevlar and PET.

• Through vertical integration of supply chain and full manufacturing experience. JuTeng is the first manufacturing company which applied composite material on 3C products.

• On laptop and mobile market, JuTeng is the leadership of both market share and technology of composite material application.

.jpg)

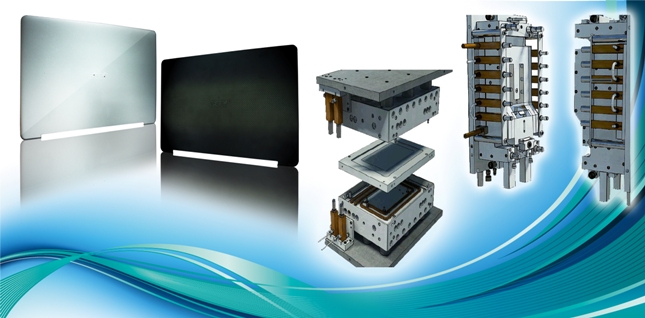

Metal material application

JuTeng has acquired variable metal production processes based on requirement of design, included CNC for Magnesium alloy and

Aluminum alloy, thixo-molding, die casting, and stamping. Moreover, with insert molding as the core technology,

JuTeng overcame the issue of receiving signal of Antenna and structure design successfully, and reduce weight of product effectively.

ROCTOOL

JuTeng control and detect heating area through heating by electromagnetic induction which IP is belonged to ROCTOOL.

Moreover, JuTeng heat and chill the model on the surface without remain high pressure vessel and thermostatic sources to enhance adaptability

of Dynamic Mold Temperature Control and increase environmental benefits.

OMR

OMR is an extension technology of IMR stands for transfer printing outside of IMR and model.

OMR is also called high pressure printing. After printing figures on transparent film, using high pressure printing to print on plastic or

metal surface three-dimensionally. This technology is eco-friendly and increase environment benefits.

MAO

Put the voltage on the part through MAO source to conduct reinforced ceramic membrane to enhance strength of the surface.

The film has superior feature for abrasion resistant, thermal resistant, and insulation.